The facility of the Faserinstitut Bremen (FIBRE) has 300 square meters of comprehensive technical production ground on the campus of the University of Bremen. As of 2019 this is further enhanced through a technical center of another 400 square meters in the EcoMaT at Bremen Airport. In both of these areas the latest technologies are used for the technical production and implementation of projects. The basic equipment includes many modern and high-quality machines and systems.

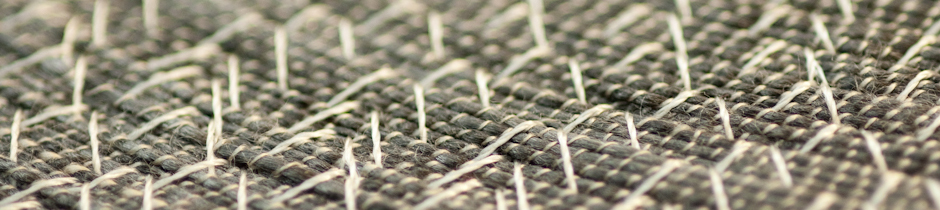

A well-trained, competent and dedicated team of technicians is available to operate the equipment, support research projects and industrial assignments. This makes it possible to reproduce a complete and extremely flexible product development process, from the individual fibre production, through the form-fitting and efficient placement of rovings to textile semi-finished products, pressing, infusing or injecting. The technical production team works closely with the testing laboratory and actively supports thesis work.