PETER

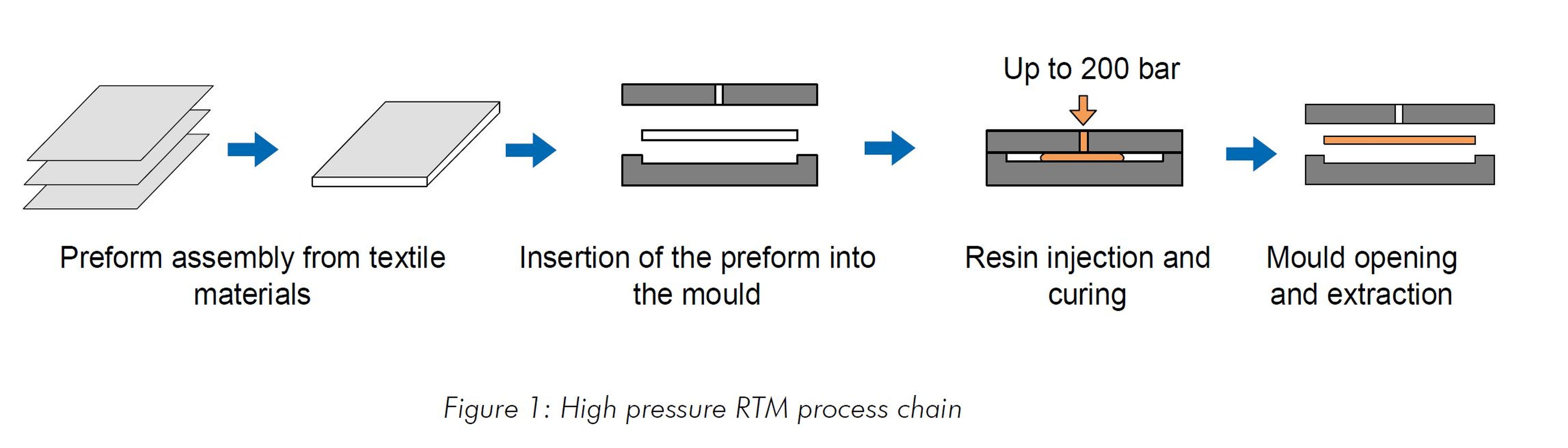

Process simulation plays an important role in composite manufacturing science. It provides significant insights, which are required to understand, optimize and design a robust and stable process. In most of the manufacturing processes of composite parts, pressure is low (< 8 bar) and its influence is considered negligible throughout most of the literature. Nevertheless, curing of epoxy resin under high pressure, up to 200 bar, occurs for example during the high-pressure resin transfer moulding (HP-RTM) process. This method results in shorter injection times as well as in the reduction of cycle times and process costs in comparison to the traditional RTM process. Its process chain is shown schematically in figure 1…read more