Hybrid Matrices

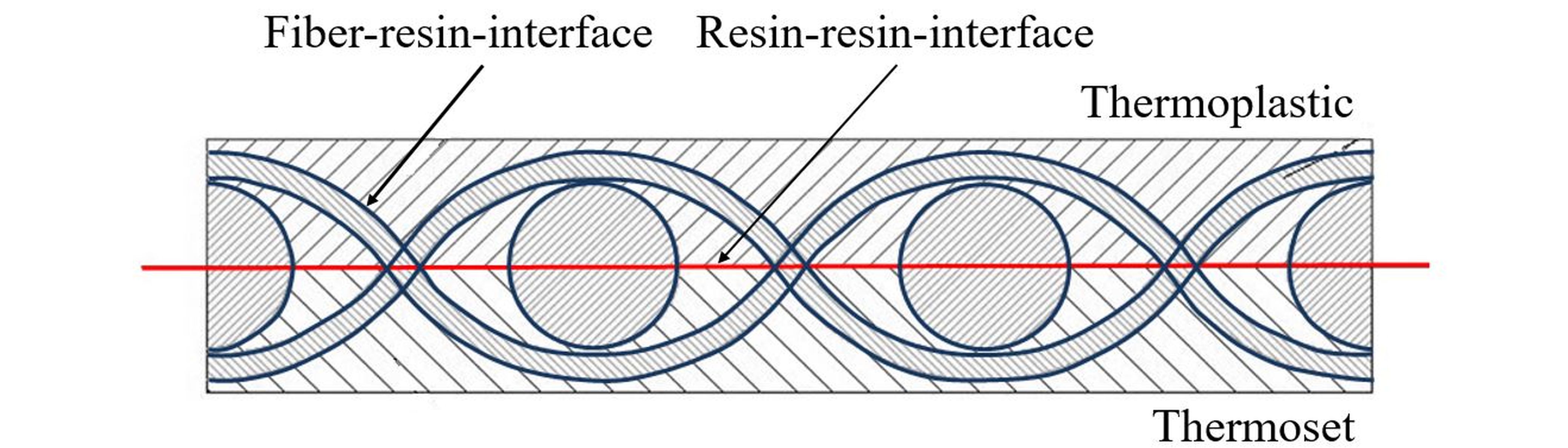

In the past years, the use of fiber reinforced plastics increased significantly due to an increasing demand for lighweight materials for aerospace. Especially the joining techniques of composites represents a current major challenge. Conventional state of the art joining techniques are riveting and bolting which expensive in mounting and heavy in weight. Furthermore, drill holes damage load-bearing fibres and reduce the mechanical performance of the composite. In the project Hybrid Matrices, a new semi-finished prepreg product will be developed. It is characterized by a thermoset compound with a single woven layer on top combining a subconsolidated side of thermoset and thermoplast (figure). During the manufacturing process, this prepreg will be laid as the upper layer of the thermoset composite to make it weldable through the thermoplastic surface for joining (fusion bonding)…read more